Yes, its Friday again and you may be lucky enough to be going out to eat at a restaurant this weekend..? Think of the chefs in the kitchen as forming a key part of the Quality Management System of the restaurant, making sure every dish is served to the best of their ability. Clearly without these efforts on quality, the product served to you the customer is not up to scratch. You would rightly be dissatisfied and may never return. The same goes for practically all businesses. If you think your quality systems could use some work, ask us how we can help. www.getbsafer.com.

Risk Management - 6 Reasons to Show Off!

We all know that businesses need to manage their risk, whether that be physical, financial, reputation, quality or any other kind…. But are you showing this off to your clients and suppliers? You should!

Heres six reasons why:

Quality Issues

It’s Friday again and naturally the main thing on your mind right now will be quality… Well it’s on our minds at least… But while working on projects it should also be on yours. Time and time again, studies show that the main contributor to quality issues on a project are erroneous, ambiguous or incomplete functional specifications and requirements or procedures. These are also the types of issues which remain concealed the longest, reappearing much later in the project to cause unnecessary headaches. Incidentally, as a general rule the later issues resurface the more they cost to rectify also. So the moral of this Friday tale? Use Front End Loading (FEL), i.e. weight your time, efforts and energy early in the project definition phase. In doing so, you’ll be doing what you can to avoid additional headaches and cost ruining your weekend…

Friday QMS

Its Friday and you naturally might be winding down, thinking about Saturday night, anticipating the big match, or indeed getting your business started with a simple quality management system (QMS)…. As most now appreciate, a functioning QMS is a crucial step towards enhancing product or service quality and customer satisfaction. Furthermore, its expected these days. And its easy to implement, following the simple steps below:

First, designate someone within the business to oversee the QMS implementation.

Define your quality objectives and KPIs based on your business goals and customer expectations.

Document your processes, procedures, and work instructions, in a clear and accessible manner.

Train your staff on these documents and establish a culture of continuous improvement

Regularly monitor and measure performance against your established KPIs, and make necessary adjustments to achieve your quality objectives.

Do periodic internal audits and management reviews will help ensure the effectiveness of your QMS.

Lastly, communicate your commitment to quality to all stakeholders, both internally and externally, to build trust and confidence in your business.

See, simple! As us how bSafer, our professional QMS software and app can help you establish or indeed improve your existing QMS. Happy Friday! https://getbsafer.com/contact-us

Leading and Lagging Indicators

How do you know if your HSE performance is good enough? Or getting better / worse? You can use leading and lagging indicators, thats how…! These can help your management understand whats happening within your business and adjust HSE strategies accordingly. Download our free one-pager guide at https://getbsafer.com/tutorials.

Story Telling...

Its Friday and its story time…. No seriously..! Stories can be a great way of motivating and inspiring your Team. Find an aspect of your activities where the way of working is very good, your Team collaborates in an efficient way or indeed any other positive aspect of your Team’s work. Make a short story about it and focus on the people and success factors that have contributed. Start your meetings by spending a few minutes to tell the story and watch the positivity spread!

As a leader, you can also use the story to see how those factors can be transferred elsewhere in your Team or business to improve ways of working in other areas. And everyone lived happily ever after….

Improve Quality for the Weekend

Its Friday so all you can think about right now is quality, right….? OK probably not. But here are some simple tips on how to improve quality anyway (save them for Monday…):

Identify the root cause of quality issues: This is fundamental and requires analysing events data to isolate the underlying cause, apply corrective actions and adjust the process to thereby prevent recurrence.

Develop your quality management system (QMS): Keep it simple - it should match your day to day business in terms of ways of working. The QMS includes policies, procedures, and processes to ensure that products and services meet customer requirements in a predictable manner.

Train employees: Training on quality principles, processes, and tools can help employees understand their role in quality delivery and enable them to contribute to continuous improvement of the QMS.

Use data to drive decision-making: Collecting and analysing data (using bSafer!) helps identify trends and areas for improvement, allowing you to make informed decisions that can help improve quality and reduce errors.

Focus on continuous improvement: Quality improvement is continuous and requires a commitment. Understanding customer feedback, and regular reviews of internal processes to identify areas for improvement will help you to consistently meet customer requirements.

Need a digital system to drive your QMS? Try bSafer for free.

Safety Culture Health Check

A strong safety culture is essential for any business - it not only helps to protect employees from harm, but it also benefits the organisation as a whole. Give your organisation a Safety Culture health check using our simple guide and checklist, completely free to download from from www.getbsafer.com.

International Women's Day 2023

Congratulations with International Women’s Day 2023 (March 8th)!

International Women's Day is a powerful reminder that women have always been and will always be forces of change, progress, and innovation. Celebrate the achievements of women around the world and commit ourselves to creating a more equitable and just world for all women. Find out more at https://www.internationalwomensday.com/

Importance of Safety Culture

Safety culture has never been more important… It creates an environment where people prioritise safety as a core value and actively work to ensure that everyone is safe. It encompasses an organisation's shared values, beliefs, and behaviours and it is reflected in how people communicate, plan, and execute their work.

Specifically, safety culture:

Protects people - Helps protect personnel from harm, reducing the risk of injuries, illnesses, and accidents in the workplace.

Improves productivity - When employees feel safe and secure, they are more likely to focus on their work and perform at their best.

Builds trust - A strong safety culture helps personnel feel valued and cared for. This leads to greater trust between management and employees, as well as among coworkers.

Saves costs - Reduces the cost of accidents, injuries, and lost work time.

Enhances reputation - A demonstration of commitment to employees, customers, and stakeholders, which can enhance its reputation and brand.

Download our free safety culture checklist, available on our resources page. No sign up or login required.

Digital Risks

Why digitalise your risk assessments and risk register with bSafer?

No more corrupted, lost or deleted files. bSafer maintains the filing system so you don´t need to, including full revision control with previous revisions easily available.

Shared files with the wrong parties? bSafer’s simple access controls allows permission to be given to all the right parties, including those outside your organisation as needed.

Spending time sharing risk? bSafer gives access automatically to all those in the group, location, department, office of choice, updated in real time.

Lost actions from risks or risk assessments? bSafer automatically sends actions directly to the actionees inbox. The status of all actions can be read in real time and followed up by admin users.

Spending time preparing risk assements? Use one of the preloaded templates or create your own template to be copied, modified and used as many times as needed.

Site personnel need the risk assessment! No problem, just tell them to check the bSafer app on their smartphone for all the relevant risk assessments and risks updated in real time.

But bSafer wont match our existing risk matrix. Then change it yourself in the admin panel. Change wording, definitions and of course the risk levels to match your own. Easy.

See how efficiently risks can be managed with bSafer. Contact us at www.getbsafer.com and try it for free.

Impact Workplace Safety

Want to make an impact on your workplace safety but don’t know where to start? Panic not. Simply use the top 10 violations published by the Occupational Safety and Health Administration (https://www.osha.gov) as a guide. For 2022, these were:

1. Fall Protection – General - inadequate measures taken to prevent falls.

2. Hazard Communication - inadequate communication of chemical hazards to workers.

3. Respiratory Protection - inadequate provision of respiratory protection to workers.

4. Ladders - equipment inadequate or incorrect use.

5. Scaffolding - equipment inadequate or incorrect use.

6. Lockout/Tagout - inadequate control of hazardous energy.

7. Powered Industrial Trucks - inadequate maintenance and / or operation.

8. Fall Protection – Training - inadequate competence.

9. PPE – Eye and Face Protection - inadequate use of.

10. Machine Guarding - inadequate protection of workers from machine hazards.

Interestingly, the top 10 for 2021 is practically the same. For more info, check out the National Safety Council’s website at https://www.nsc.org/newsroom/osha-reveals-top-10-safety-violations-for-fiscal-y.

Quality Audit Plan

Is your Quality Audit Plan gathering dust in the bottom of a locked filing cabinet somewhere? Then digitalise it! The audit plan outlines the scope, frequency, and objectives of the audits that you plan, and can help your business identify and fix any weaknesses or inefficiencies in its processes. It can also provide your business with valuable insights into its performance, and help identify improvements that can increase efficiency, reduce costs and increase customer satisfaction.

An audit plan can also help compliance with regulatory requirements, and demonstrate to stakeholders such as investors and customers, that your business takes its Quality Management System seriously. Ask us how to simply and quickly digitalise your Quality Audit Plan and other quality activities such as inspections and checkpoints. www.getbsafer.com

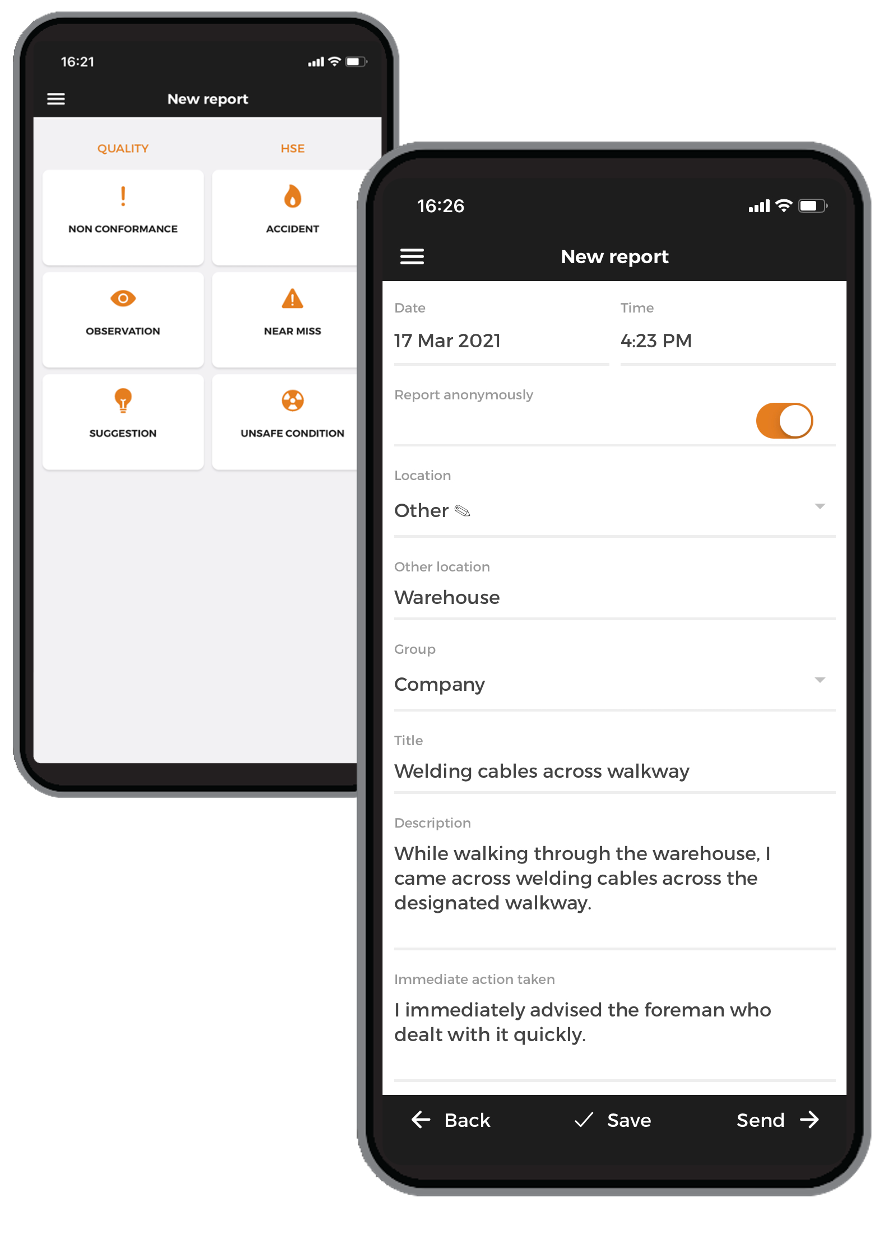

Why a good reporting system is essential!

Safety reporting isn’t about throwing a few suggestions into the box next to the coffee machine… An active safety reporting system, i.e. one that is used, followed up and closed out will help provide valuable information that can help organisations improve safety, reduce risk, and create a safer and more efficient work environment. Specifically, a good system will:

Reduce the risk of future accidents and incidents.

Increase awareness of hazards helping identify areas of improvement.

Improve risk management by collecting data on incidents and near misses helps to assess risk, prioritise safety improvements, and implement effective risk management strategies.

Enhance learning opportunities by analysing and learning from incidents and near misses, allowing identification of systemic issues thus enabling changes to prevent future incidents.

Improve compliance to meet regulatory requirements, achieve client expectations and demonstrate a commitment to safety and quality.

Improve company culture and continuous improvement, where employees feel empowered to speak up about potential hazards.

All this can be achieved by a simple digital QHSE and Risk Management tool. Say no more…

Go Digital! Errrr slowly....

Digitalisation isn’t just the latest buzz word, its an ongoing transition to a more collaborative, connected and efficient way of working. For quality, HSE and risk functions it may be best with a gradual implementation of digital tools. As a first step take say your HSE reporting (incidents, near misses, observations etc) online to your PCs and mobile phones, roll out this to your business and allow it take hold. As a second step, include your risk register and risk assessments. And so forth. With bSafer, each module can be toggled on/off through your admin panel such that only the functions you implement are visible. So you can start with the Reporting Module, then later gradually add and roll out the Risk, Activities, Actions, Emergency, Statistics, ERT Modules. We can help and advise with your digital QHSE and Risk transition. Contact us at www.getbsafer.com.

Digitalisation in 2023 Part 2

In todays marketplace, the margins between strong, efficient businesses are fine. With increasing digitalisation, the margins are getting even finer. That’s why it is important to leverage low cost, high performing digital tools such as bSafer to deliver the absolute highest quality products and services to your clients. This increases customer satisfaction and loyalty, reduces cost through reduced waste and rework, builds a stronger reputation and ultimately can lead to increased success and growth. Contact us at www.getbsafer.com for a friendly chat or ask us for a free demo or trial.

The bSafer Team

Happy New Year

Happy New Year to all our customers (past, present and future), our colleagues, partners and of course all our families and friends. Wishing you all the best for 2023.

The bSafer Team

Digitalisation in 2023

The digital transition moves faster forward as 2023 rolls into town. Digitalisation of QHSE and risk management functions has moved from a nice-to-have selling point, to an absolute business necessity. According to PTC, back in 2019 already 70% of organisations had or were working on a digitalisation strategy. As more organisations realise their digital aspirations, they are increasingly looking for the same in their collaboration partners and suppliers. Essentially, rocking up with a spreadsheet of risks or a bit of paper with a quality activity plan no longer makes the grade. The solution is a powerful, user-focused software solution which most importantly is easy to implement and cost effective. We at bSafer can help with that. Contact us online, www.getbsafer.com for a friendly chat.

Merry Christmas!

We wish all our friends and customers; past, present and future(!) a very Merry Christmas and all the best for the new year. From the bSafer Team.

PS Thanks to www.freepik.com for the lovely Christmassy image.

Internal Audits

There’s going to be an internal audit?! Run away!! No wait, come back... Internal audits are really not that bad. In fact, they can be a great way of identifying and fixing small inefficiencies in your business, and indeed help find better, more effective ways of doing things, saving your personnel both time and energy. What’s not to like? Not only that, internal audits are a great way to signal to your personnel and customers that your business takes quality, health, safety and environmental issues seriously. Help realise your audit activity plan by planning your 12 months of internal and external audits up front using a powerful digital QHSE tool such as bSafer. Ask us how at www.getbsafer.com.